KaStar978 Firerated MS Polymer Sealant

- Product Details:

- Place of Origin: Guangdong, China (Mainland)

- Brand Name: kater

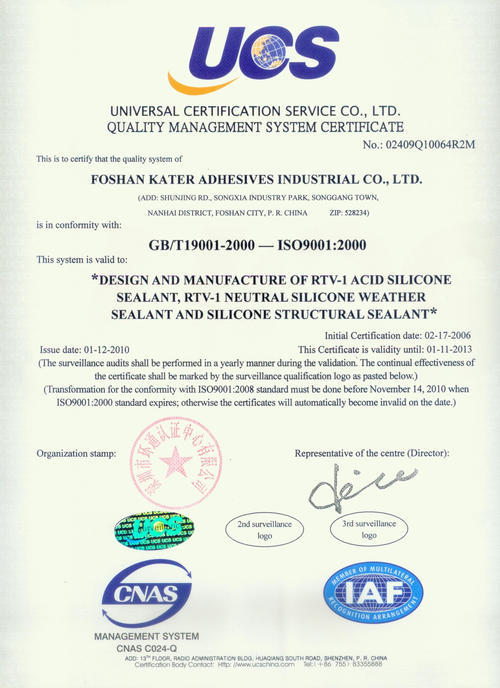

- Certification: ce

- Model Number:

- Packaging Details:

- Delivery Time:

- Payment Terms: L/C,T/T,Western Union

- Supply Ability: 5000 tons per month

KaStar978 Firerated MS Polymer Sealant is a one-component moisture-solid MS Polymer Based Sealant, which has execellent flame retardant and adhesive sealing performance, no corrosion to the substrate,No pollution, no pollution to the environment, and good adhesion to metal, glass and other substrates.

● The flame-retardant grade reaches EN45545-2 HL3, with strong flame-retardant performance.

● Low smoke emission in the burning state.

● Good UV resistance and weather resistance.

● It has good adhesion to a variety of substrates.

MS Firerated is non-hazardous, will not emit halogenated by products under fire conditions and contains no raw materials known to have an oestrogenic effect on the environment. The sealant offers excellent levels of adhesion to most construction substrates and can be overpainted with oil, polyurethane or latex paints.

● Not suitable for freezing or damp, silicone oil-containing base surface and silicone rubber.

● The surface of the substrate to be adhered must be clean and dry, free of dust, oil and water stains. Adhesive substrate should be used for cleaning with cleaning agent. Otherwise, it may cause bonding failure.

● Temperature and humidity have a great impact on the surface for drying and curing of the sealant, and the construction environment is recommended Temperature 5~35℃, humidity 50~70%RH.

● The node part can be modified and smoothed with a scraper or rigid foam strip, and the ground is partially modified.It can be smoothed with soapy water.

● For construction methods, please refer to the construction instructions or consult our technicians.

They should be protected from water, frost and adverse air conditions.

They should be kept dry and cool on wooden pallets at between +10 °C and +25 °C in moisture free conditions.

The opened products should be consumed immediately.

Shelf life is maximum 9 months conditional to complying with the aforementioned storage conditions.

For information and advice on the safe handling, storage and disposal of chemical products, users shall refer to the most recent Material Safety Data Sheet containing physical, ecological, toxicological and other safety-related data.

The technical data contained herein is based on our present knowledge and experience and we cannot be held liable for any errors, inaccuracies, omissions or editorial failings that result from technological changes or research between the date of issue of this document and the date the product is acquired. Before using the product, the user should carry out any necessary tests in order to ensure that the product is suitable for the intended application. Moreover, all users should contact the seller or the manufacturer of the product for additional technical information concerning its use if they think that the information in their possession needs to be clarified in any way, whether for normal use or a specific application of our product. Our guarantee applies within the context of the statutory regulations and provisions in force, current professional standards and in accordance with the stipulations set out in our general sales conditions. The information detailed in the present technical data sheet is given by way of indication and is not exhaustive. The same applies to any information provided verbally by telephone to any prospective or existing customer.

Chemical Base

MS Polymer

Curing System

Moisture

Density

1.5 ± 0.1 gr/ml

Appearance/Color

Paste,Black

Skin Dry time

40 min (23°C and %50 R.H.)

Speed of Squeeze

500g/min GB/T 13477.4

Hardness Shore A

40

Elongation at break

260

Tensile strength

2.2 N/mm2

Smoking Density

80

flame-retardant grade

V-0

Temperature Work

-40oC and +90oC

Packing Specification

Product Type

Volume

Package

Clear

300ml

24

Clear

600ml

12

FEATURES

INSTRUCTIONS

RESTRICTIONS

STORAGE AND SHELF LIFE

SAFETY & DISPOSAL

PROPERTIES DISCLAIMER

Typical Physical Properties

- Other Products

- Kater Adhesive Industrial Co.,Ltd

Tel:0086-13924533378

Fax:0086-731-8987 0169

Contact Person: Miss. Sunny customer service

Phone:0086-13924533378

Skype:ylsealant

Email: sales@kastarsealant.com

Send your inquiry directly to us

English

English Español

Español Русский

Русский